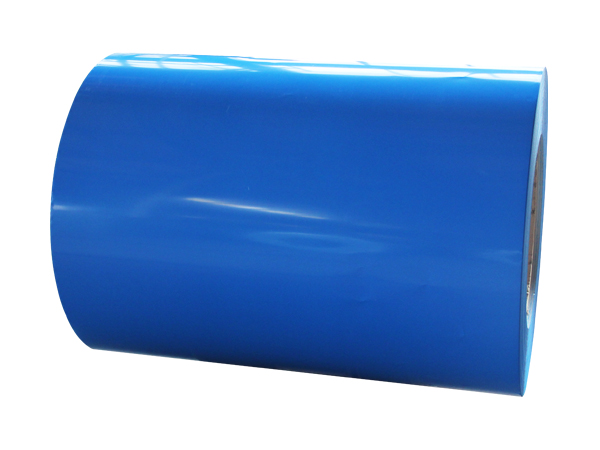

As the derivative product from the HDG sheet and also as a deeply processed product, the colored coating steel plate is manufactured by painting colorful coating materials or by conglutinating organic film on the basic sheet after the proper surface treatment, which is very suitable for the further cold rolling shaping process. Basically, the painted sheet is layered into three layers including the basic steel sheet, the galvanized zinc and the painted layer. As a newly born material, the painted sheet enjoys many attractive advantages such as favorable decrative trait, easy shapping trait, high corrosion resistance and powerful cohesion of the painted layer which ensure the color can be retained for a long time without fading.

Endowed with dual advantages exiting in the steel sheet and the organic materials, the painted sheet is highlighted by its mechanical strength and easy-shaped performance, which is similar to the steel sheet, and also by its decorative effect and corrosion resistance, which is similar to the organic materials. Furthermore, the painted sheet enjoys good economic performance in the actual constructions. For example, high-efficiency construction can be achieved with wooden building materials replaced by painted steel; The energy will also be saved; The pollution caused by the secondary process on the steel sheet can be avoided efficently. As a high-quality composite, the painted sheet has become an ideal composite material in some industries such as architecture, light industry, automonile manufacturing, electrical appliance and transportation, etc.