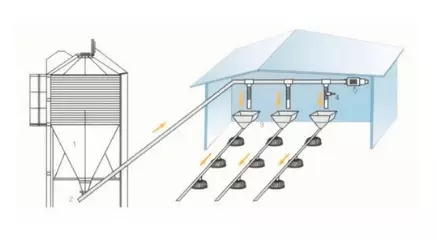

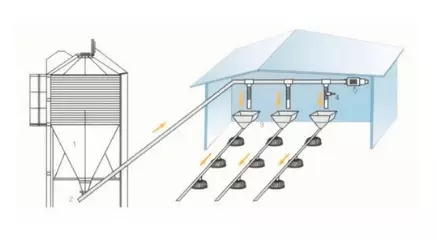

Features of Feed silo

As a professional manufacturer of storage equipment, we have developed, designed and manufactured assembly steel silos.The standard ladder and fence is safe and reliable.

The feed bin is fastened strongly and sealed.

Our feed bin made by high quality galvanized steel sheet.

Bin lever indicators at bottom and roof.

.jpg)

Introduction and Advantages:

1. The hopper bottom steel silo series is specially designed by senior engineers in our company, with high-quality galvanizing board.

2. Hopper angles can be 45° and 60°,among which 60° conical bottom is usually used to store larger pellet and powder materials with high viscosity.

3. All BODA silos are precision engineered from high strength, 80mm x 14mm low profile corrugated steel plate, galvanized to 275 g/m2 (or optional 450 g/m2).

4. Lower basic cost with lightweight, low request for foundation, low consumption of steel.

5. High degree of standardization. We can produce the standard components which can be installed on-the-spot. Simple, easy and efficient to install within a short amount of time due to superior component design which are connected by standard bolts.

6. Easy to maintain. As the parts of the silo are connected by standard bolts, so it is easy to remove or repair it.

7. The life cycle of the silos can come up to 30-50 years long. The products are designed comply with the national standard of GB50322-2001.

WZH feed tower chicken farm cosists of silo body sheets, silo lid, collar, hopper sheets, roof panels, silo legs, ladder system. All parts are manufactured to engineering design specifications and quality checked to ensure hassle-free assembly and use

Silo body

Constructed with hot-galvanized corrugated steel plate;zn-coat thickness≥275g per square meter.

Silo body is 1250mm wide,fit for different thickness requirements(1.0-1.5mm)

All steel plate joints are fixed by Grade8.8,M10 bolt and seal gums,ensuring no leaking seams,security and long operating life.

.jpg)